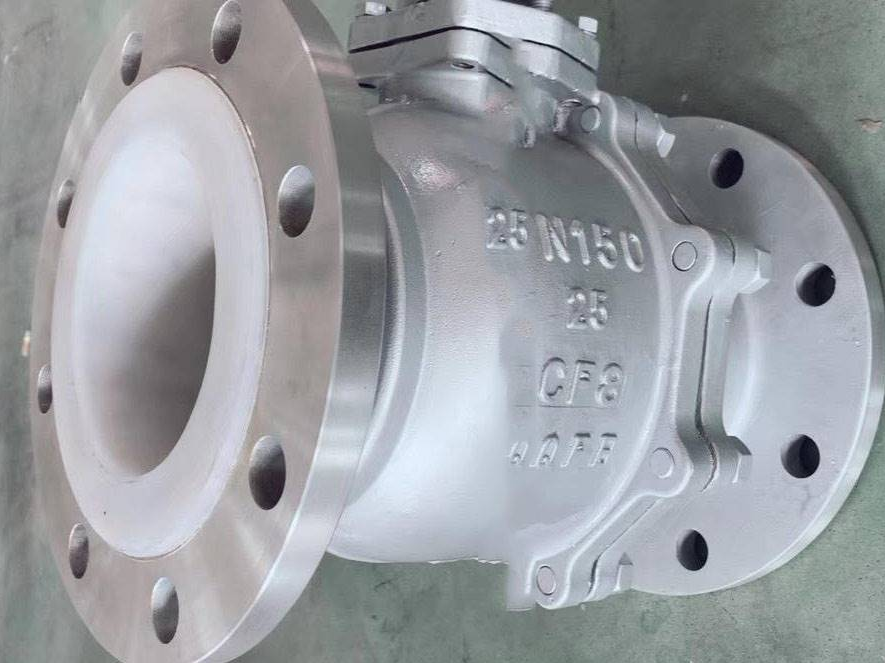

Corrosion refers to the process of material degradation and damage caused by surrounding media (water, air, acids, alkalis, salts, solvents, etc.). It can be classified by material type (metal/non-metal corrosion) or surface morphology (uniform/localized corrosion). Localized corrosion includes pitting, stress corrosion cracking, intergranular corrosion, crevice corrosion, galvanic corrosion, and erosion corrosion.

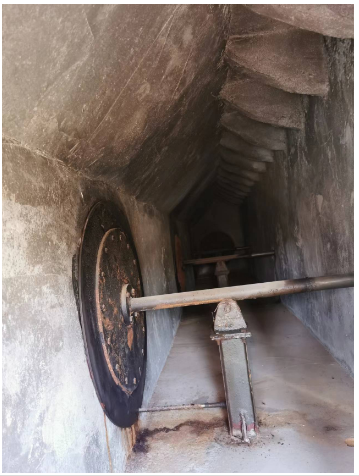

In the chemical industry, organic waste gases often exhibit complex compositions, fluctuating concentrations, variable flow rates, and corrosive components. While RTO systems are highly effective for treating such emissions, their valves frequently face severe corrosion—especially in pharmaceuticals, pesticides, and advanced materials sectors—due to inorganic/organic acids and halogens in VOCs. This corrosion compromises system performance and shortens equipment lifespan.

Occurs when metal surfaces react chemically with surrounding media (e.g., acids/alkalis).

Arises from redox reactions between metals and electrolytes. Moisture films on metal surfaces act as electrolytes, accelerating corrosion.

Caused by microorganisms (e.g., sulfate-reducing bacteria) colonizing valve surfaces.

(2) Economic Losses: Increased maintenance/replacement costs, production downtime, and product quality issues.

(3) Performance Degradation: Corrosion causes valve leakage or failure, disrupting industrial processes.

Eliminating electrochemical reactions;

Forming passive films (e.g., oxide layers) on metal surfaces;

Replacing metals with non-electrochemical material.

Corrosion-Resistant Materials

(1)Select materials (e.g., stainless steel, alloy steel, plastics, aerospace-grade alloys) suited to operational environments.

Apply protective coatings (e.g., synthetic resins, rubber latex, or solvent-based paints) to isolate valves from corrosive media.

Add inhibitors to media to form protective films on metal surfaces.

Routine inspections to detect and address early-stage corrosion.

Use impressed current to make valves cathodic, preventing electrochemical corrosion.

ConclusionValve corrosion prevention is a systematic effort spanning design, manufacturing, operation, and maintenance. Effective strategies include material selection, coatings, inhibitors, maintenance, cathodic protection, and microbial control. Tailoring solutions to specific corrosion mechanisms ensures optimal valve performance, safety, and cost efficiency.