Temperature control plays a vital role in the whole operation process of rotary RTO. It is interlocked with other actuators of the system (such as various fans, proportional control valves, air valves, etc.) to realize the stable and reliable operation of RTO. The stable control of temperature helps to stabilize the waste gas treatment efficiency above 99%, and realizes the goal of reducing energy consumption and bringing economic benefits to the enterprise!

After several temperature rise tests of ceramic tiles, the author summed up a set of the most energy-saving RTO furnace temperature rise control curve. In the heating stage, the heat source mainly comes from the combustor on the furnace body. The combustor is equipped with an ignition controller. Its main function is to control the ignition action. Two temperature control meters with 485 communication function are also installed on the combustor control cabinet to collect the furnace temperature in real time. One of the temperature control meters adjusts the ratio regulating valve of the combustor according to the set temperature sent by PLC in real time, so as to realize the control of small and large fires. Another temperature control meter is used for high temperature alarm control and standby temperature detection. Users only need to set the temperature rise curve on the touch screen, and the PLC controller will automatically control the temperature in real time.

The temperature control of RTO can be roughly divided into three stages:

1. Temperature rise stage (no waste gas access)

During temperature rise, after receiving the temperature rise signal inside the PLC, open the fresh air valve at the inlet of the main fan, close the exhaust gas access valve, close the emergency discharge valve and heat exchange valve, start the rotary valve (40Hz), combustion supporting fan, purging fan and main fan (15Hz constant frequency). After purging for 3 minutes, the combustion engine starts to ignite, and officially enters the temperature rise stage after successful ignition. The temperature control meter will receive the real-time set temperature sent by PLC in real time, compare it with the current temperature, and adjust the PID proportional valve to realize the control of small and large fires. At this time, the ceramic heat storage brick will slowly heat up and store the heat in the ceramic heat storage brick.

2. Production stage (waste gas access): when the furnace temperature reaches the set access waste gas temperature (generally 800 ℃), close the fresh air valve at the inlet of the main fan and open the waste gas access valve. After the exhaust gas is connected, the host automatically realizes PID adjustment according to the negative pressure value (generally negative 100~150pa) set by the front-end wind pressure meter to ensure that it is in a constant micro negative pressure state. Different concentrations of exhaust gas will have different states after being connected. One is that it does not reach the self-balance state. At this time, the control system automatically adjusts the proportional valve of the combustion machine according to the furnace temperature to the most energy-saving control proportion to realize low fire control. One is that after the organic waste gas is connected to the furnace body for combustion, there is surplus heat generated, and the furnace temperature still rises after the waste heat is supplied back to the production line. At this time, after the proportional valve of the combustor is adjusted to the minimum proportion, the combustion mechanism Fire State is executed. In this process, the proportional valve of the burner is automatically adjusted by judging the real-time temperature of the furnace, and the furnace temperature is controlled at 800 ℃ -820 ℃. When the temperature exceeds 820 ℃, the burner is in the off state, and the whole system is in reactive operation.

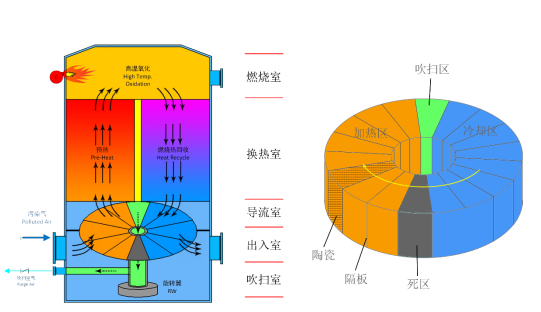

The furnace body is divided into 12 sectors, and four functional zones are divided for the 12 sectors (see the attached figure). The four functional zones are: purging zone, heating zone, cooling zone and dead zone. The furnace body is divided into five chambers from top to bottom (see the attached figure), which are: combustion chamber, heat exchange chamber, diversion chamber, inlet and outlet chamber, and purging chamber. The exhaust gas first enters the heating area, then passes through the diversion chamber, heat exchange chamber, combustion chamber, after high-temperature combustion in the combustion chamber, and then passes through the cooling area. When entering the cooling area, it passes through the heat exchange chamber, diversion chamber, inlet and outlet chamber respectively, and then enters the smoke flushing, which is discharged after reaching the standard. When the exhaust gas enters the heating zone, the heat generated after oxidation and decomposition is stored in the ceramic brick. At this time, the temperature of the exhaust gas will rise sharply when it passes through the heating zone from bottom to top. Until the exhaust gas enters the combustion chamber for combustion, the standard gas will pass through the cooling zone from top to bottom, and the temperature will be stored in the ceramic heat storage brick again. For the next cycle, the exhaust gas enters the storage heat energy, and the standard gas will pass through the heat exchange chamber, guide chamber Enter and exit the room and finally enter the chimney to discharge into the atmosphere!

Overtemperature alarm processing (generally 880 ℃): first, the user will be reminded of overtemperature. Secondly, the program will let the emergency discharge valve enter the PID regulation mode. PLC compares the real-time temperature of the temperature control meter with the PID set temperature, and then adjusts the output 4~20ma signal to adjust the opening of the analog emergency discharge valve, so that the furnace body temperature will remain within the normal working temperature range after adjustment. When the temperature of the furnace drops below 870 ℃, the PID regulation is closed and the emergency discharge valve is closed.

Overtemperature shutdown waste gas treatment (generally 900 ℃): when the emergency discharge valve is fully opened, the temperature of the furnace body still rises until it rises to 900 ℃, it is necessary to switch the waste gas access, and introduce fresh air for cooling.

3. Cooling stage (no waste gas access): when receiving the shutdown signal, open the emergency discharge valve, close the exhaust gas access valve, and open the fresh air valve to cool down. When the temperature drops below the set value, close the main fan, purging fan, and combustion supporting fan.