The company primarily produces paper packaging materials, aluminized films, barrier films, capacitive conductive films, high-transparency conductive films, resistive conductive films, and other functional films. It is a national high-tech enterprise that integrates three major businesses: eco-friendly packaging materials, high-precision aluminum foils, and functional films.

Source of Exhaust Gases:

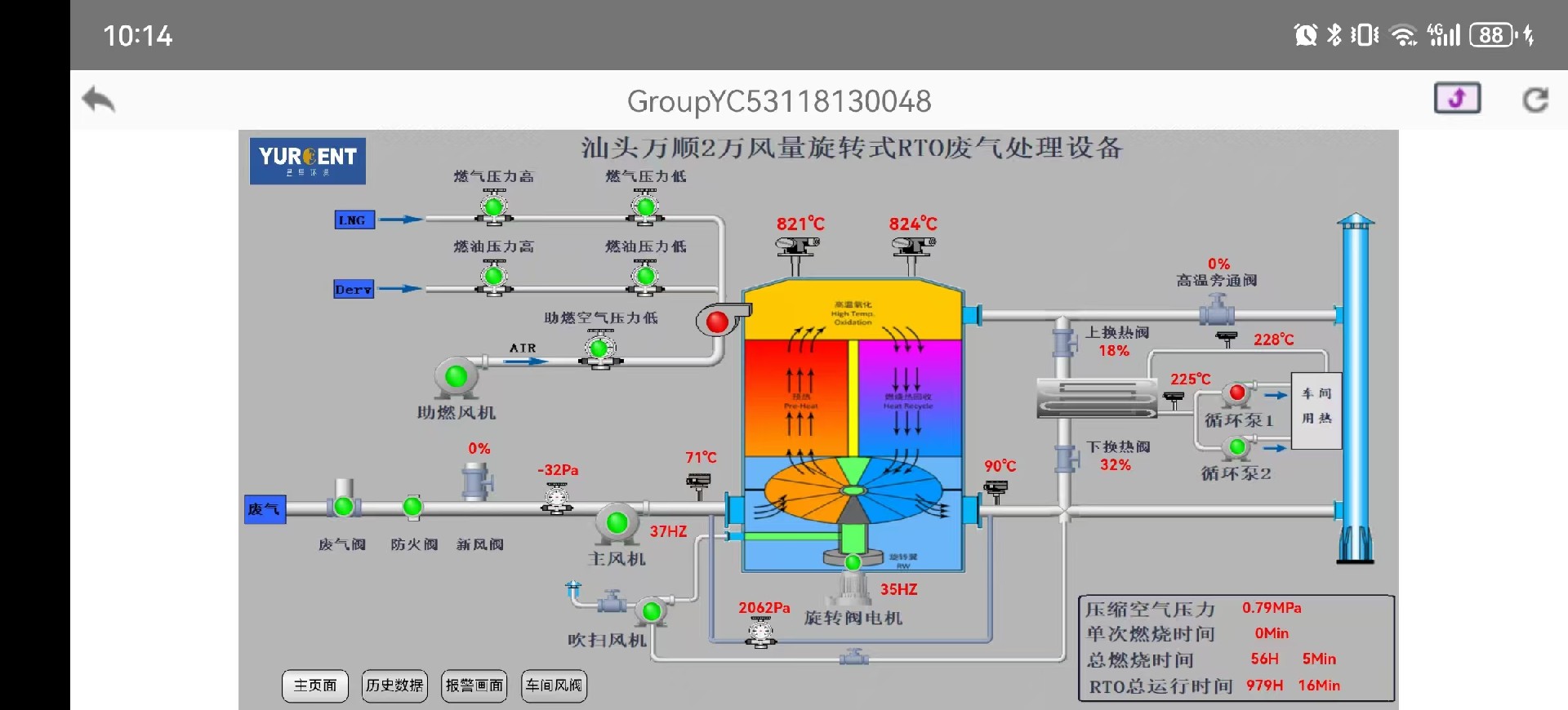

This project primarily treats the exhaust gases generated by 4 coating lines in the production workshop, with a total exhaust gas flow rate of 20,000 m³/h.

Main Components of Exhaust Gases:

Ethyl acetate, n-propanol, methyl ethyl ketone, n-propyl acetate, etc., with an exhaust gas concentration of 6,000 mg/m³.

· Based on the actual conditions of the client's workshop, the project plans to replace the existing bed-type RTO with a 20,000 m³/h rotary valve RTO utilizing third-generation technology to treat the VOCs exhaust gases emitted during the coating machine's production.

· Additionally, a thermal oil waste heat boiler will be configured to recover the waste heat generated by the exhaust gases. The recovered heat will be supplied to the production line in the form of thermal oil, meeting the heating requirements of the production equipment.

The RTO achieves a purification efficiency of over 99%, ensuring compliance with environmental standards while enabling the recovery and utilization of waste heat.