Discussion on the control of Dioxins during RTO operation

Huang zhaobiao

Dioxins, usually white crystals, are a colorless, odorless and highly toxic liposoluble substance. They are composed of one oxygen atom linked to two chlorine substituted benzene rings, forming polychlorinated dibenzofurans (PCDFs). Each benzene ring can be substituted with 1-4 chlorine atoms, forming numerous isomers, among which PCDDs have 75 isomers and PCDFs have 135 isomers.

Dioxins are secondary pollutants generated during the incineration of VOCs. They have varying degrees of toxicity, stable property, wide distribution and enormous harm. Their toxicity is 130 times that of cyanide and 900 times that of arsenic, and they have irreversible “teratogenic, carcinogenic, and mutagenic” toxicity. They are considered “one of the most dangerous chemical substances in the world”. Chlorine containing organic exhaust gases will produce dioxins during the RTO incineration process. How to effectively control the production of dioxins is a key issue of concern for RTO designers and business owners.

1.Conditions for generation of dioxins

Benzene ring: A certain number of benzene rings need to be provided, whether in the synthesis reaction or in the heterogeneous reaction of precursors.

Chlorine source: Chlorine containing substances are required to provide a certain amount of chlorine atoms in the formation process of dioxins.

Temperature: Temperature is one of most factors affecting the formation of dioxins (300-500℃).

Metal catalyst: In the synthesis reaction and precursor catalytic reaction, even with sufficient carbon and nitrogen source and suitable temperature, without the presence of catalyst, there will not be too much generation of dioxins.

Oxygen: In the experiment, it was observed that under hypoxic conditions, the concentration of dioxin production began to decrease. The presence of oxygen is necessary in the synthesis reaction, and as the oxygen concentration increases, the concentration of dioxin generation generally also increases.

Water: Water plays a certain role in the generation of dioxins. As an additional oxygen source, the presence of hydrogen reduces the oxidation degree of dioxins. Provide hydroxyl radicals.

Reaction time: Numerous experiments have shown that at suitable temperature, after 5-30 minutes, the generation rate of dioxins increases sharply and is completed with 2-4 hours.

High temperature decomposition of dioxins

When the incineration temperature reaches 750℃, dioxins begin to decompose and the C-Cl bond first breaks. When the temperature reaches above 800℃, C-O bond breaks. At this temperature, in a short time, benzene ring substances in the above two decomposition products still exist, which is called an unstable structure and still a prerequisite for the generation of dioxins. It is a reversible reaction process and can generate dioxins again under appropriate temperature.

When the incineration temperature reaches above 850℃, the precursors of dioxins (benzene ring substances) can quickly and completely decompose to inorganic substances, causing the benzene ring organic compounds, which are precursors of dioxins, to disappear. Regardless of the temperature range, dioxin substances will not be generated again, which is an irreversible reaction process.

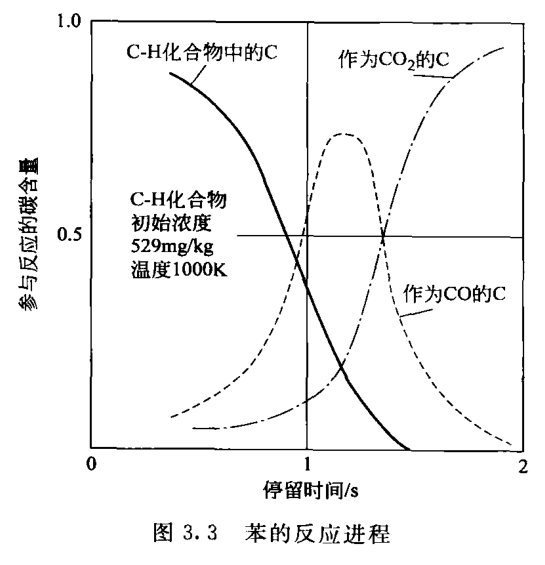

Benzene compounds will decompose into benzene during high temperature incineration. The above figure shows the reaction process of benzene during high temperature incineration. From the figure, it can be seen that the benzene ring organic compounds disappear when the residence time is greater than 1.2 seconds. At present, the common view is that when the exhaust gas temperature reaches 850℃ and stays 1.5 seconds, when the temperature reaches 1050℃ and stays a few thousandth of a second, dioxins can be completely decomposed into inorganic substances. The prerequisite substances for producing dioxins no longer exists, and dioxins are completely eliminated.

Explanation on reducing dioxin production during RTO incineration process.

Residence time: Reasonably design the size of the combustion chamber.

Combustion temperature: Ensure that the combustion temperature of exhaust gas in the combustion chamber is between 850-950℃.

Eddy: The flue gas is fully mixed in the high temperature area of the furnace, allowing it to burn thoroughly.

Shorten the rapid cooling time of high temperature exhaust gas in the regenerative chambers, ensuring that the residence time of exhaust gas in the medium temperature range (300℃~500℃)is less than 0.5s, thereby reducing the production of dioxins.

Thermal storage ceramics have adsorption functions, and the dioxins adsorbed in the ceramics will re-enter the combustion chamber for high temperature decomposition with the purging air.