The VOCs treatment project of Zhongshan King Label New Material Co., Ltd., contracted by Yurcent Environment, adopts the technical route of “ Rotary Valve RTO + conduction oil waste heat recovery system+ secondary hot air waste heat recovery system” to comprehensively treat the production exhaust gas of the film coating workshop. After long-term stable operation, the purification efficiency of environmental protection equipment has stably reached above 99%. And the waste heat conduction oil boiler heats up the conduction oil to supply heat to the production equipment. This project achieves the environmental protection treatment standards while carrying out the waste heat recovery and utilization.

King Label company was established in 1998, located in Zhongshan, Guangdong, China. It serves the fields of automobiles, electronic appliances and daily chemical products, mainly products PET/TAC HC explosion proof film, low flash point PET/TAC AG explosion proof film, PET/TAC HC AR explosion proof film, PET/TAC AG AR explosion proof film, protective film, UV debonding cutting protective film and other products.

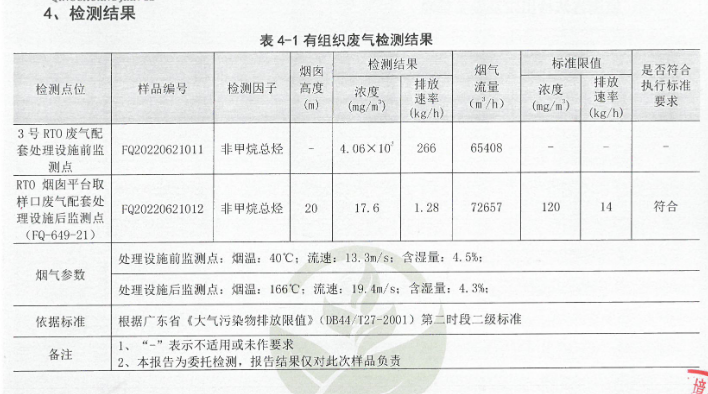

The exhaust gas mainly comes from coating machine of production workshop, and its main pollutant VOCs are organic exhaust gas such as ethyl acetate. The parameters of exhaust are shown in the table bellow:

Enterprise | Zhongshan King Label New Material Co., Ltd. |

Total solvent usage | 440-500kg |

Type of solvent | Ethyl acetate and others |

Concentration | 5439mg/m³ |

Temperature | 60℃~90℃ |

This project was purchased by Zhongshan King Label New Material Co., Ltd. in two phases. According to the coating line launch plan, two sets of “70000Nm³/h Rotary Valve RTO +waste heat conduction oil recovery system +secondary hot air waste heat recovery system” treatment route was adopted to maximize the waste heat recovery and reduce the enterprise energy consumption.

Treatment efficiency | Emission concentration | Type of waste heat recovery | Waste heat recovery amount | Benefit of waste heat recovery( calculated by electricity) |

99% | ≤50mg/m³ | Conduction oil +hot air | 1,300,000kcal/h | 750 yuan/h |

◆ High treatment efficiency, with a treatment efficiency of over 99%, and a continuous VOCs emission value of less than 50mg/m³.

◆ Adopting a waste heat conduction oil boiler, the usable combustion heat is recycled and supplied to the production line in form of conduction oil, meeting the production heat demand of coating machine;

◆ Adopting a secondary hot air waste heat exchanger to further recycle the usable energy, heating fresh air to supply heating equipment in workshop, further reducing the energy consumption of enterprise workshop.