In March, 2021, the VOCs treatment project for the raw material drug production of Hubei Huisheng Pharmaceutical, contracted by Yurcent Environment, was successfully passed FTA , meeting the various indicators stipulated in the contract, and was put into operation smoothly. As of April 2023, this project has been running steadily for two years.

Project Background:

Hubei Huisheng Pharmaceutical Co., Ltd. was established in November 2009. It is a joint-stock company jointly invested by Huibei Guangji Pharmaceutical Co., Ltd.( stock code 000952), Xianning Jinghui Pharmaceutical Co., Ltd., and Hubei Harmony Co., Ltd. It is a high-tech company designated by State Food and Drug Administration to produce VB6. It is recently one of the most important VB6 production manufacturers both domestically and internationally

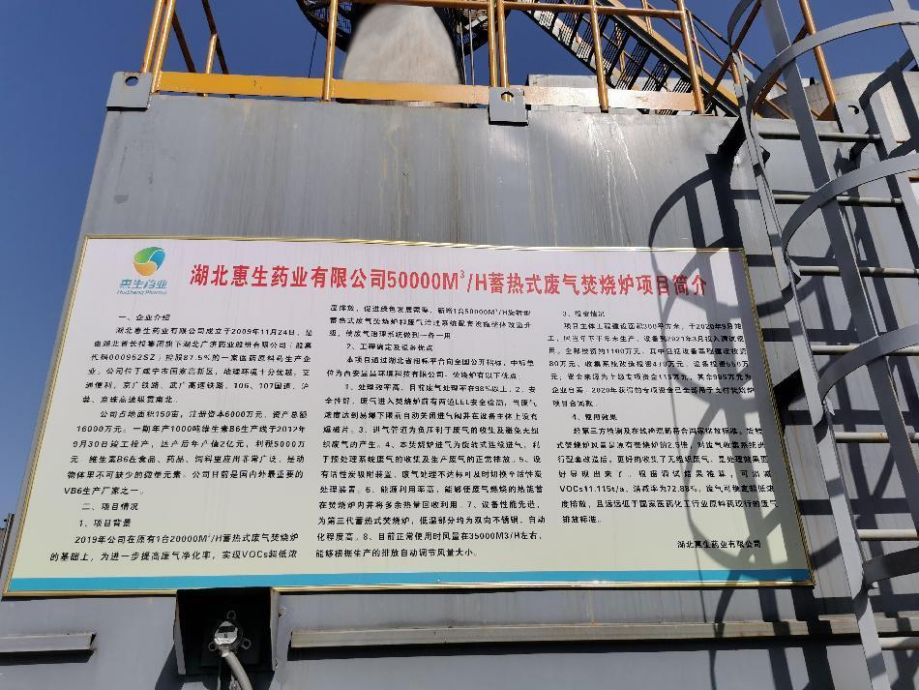

Hubei Huisheng Pharmaceutical originally had one set of 20000Nm3/h three bed RTO. In order to further improve the exhaust gas purification efficiency, achieve the ultra-low concentration emissions, and promote the green development, a new set of 50000Nm3/h Rotary Valve RTO treatment system was added to treat the exhaust gas generated by the VB6 production device and its supporting projects.

Source of Exhaust gas

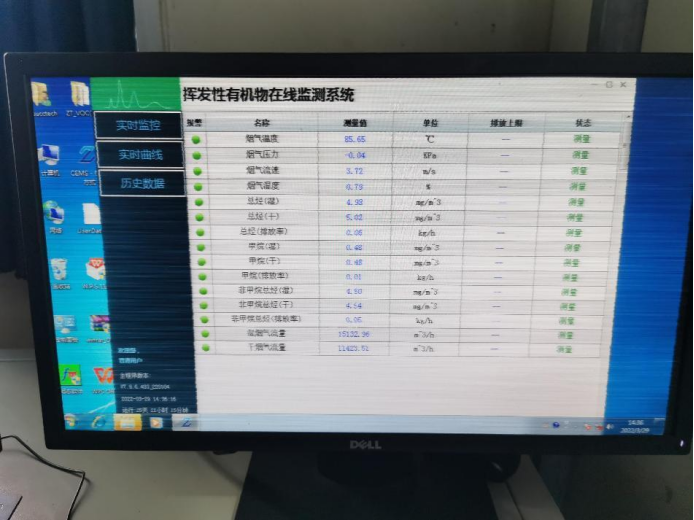

The exhaust gas comes from the production line of raw materials and derivatives . The main components include ethanol, benzene, toluene, ethyl acetate, triethylamine, oxazole, HCL, heptacyclic acid, n-butanal, methane, hydrogen sulfide, and ammonia.

Design Advantages:

The flow rate of the project is about 20000Nm3/h, and the concentration of mixed exhaust gas is between 7000mg/m3 and 15000mg/m3. The project adopts a Rotary Valve RTO of 50000Nm3/h to treat the exhaust gas generated by the raw material drug production and its supporting projects.

Project advantages:

1、High purification efficiency, stable above 99%;

2、High safety level: complete supporting safety facilities and safety interlocking control;

3、High thermal efficiency: recycling and utilizing excess heat while meeting RTO self operation, turning waste into treasure;

4、Complete process supporting facilities: the emergency discharge pipeline is equipped with an active carbon adsorption device to ensure compliance with standards during emergency emission.

5、The equipment has a high corrosion resistance level: the low temperature part is made of acid corrosion resistant bidirectional stainless steel and super stainless steel, with a thorough drainage structure at the bottom.

6、Advanced anti-blocking design: concentration control of the characteristic substances in the RTO inlet, design of access doors in the middle area and the thorough drainage structure at the bottom.

7、High degree of automation, full automatic operation of equipment.

Operation effect:

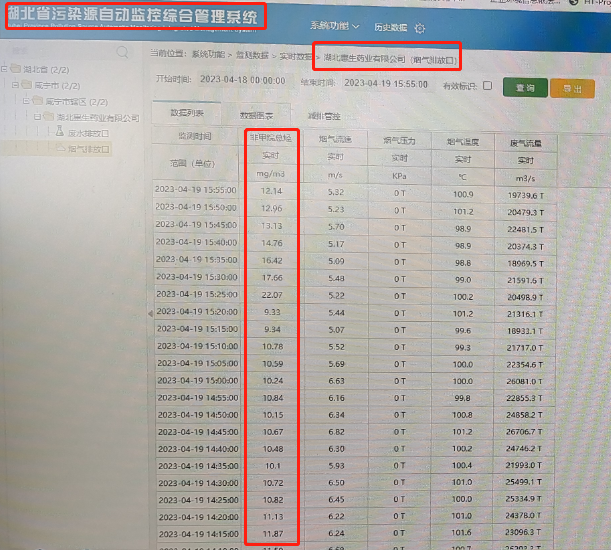

The project has been in continuous operation for two years, with multiple performance tests and 24-hours continuous VOCs emission concentration online testing meeting the national emission standards. The volume of Rotary Valve RTO is 2.5 time that of the original incinerator. After the transformation of the exhaust gas collection system, it can better collect and treat the unorganized exhaust gas. According to the calculation of import and export concentration, the project can reduce VOCs by 11.115t/a , with a reduction rate of 72.88%. The project can achieve stable ultra-low concentration emission, which is far lower than the current emission standard for raw material drug in the national pharmaceutical and chemical industry.

Xi’an Yurcent Environment has numerous cases in the field of VOCs treatment in pharmaceutical and pesticide production, with a leading number of cases and rich experience in China, which established a high quality model project for VOCs treatment of pharmaceutical and pesticide production.