The regenerative thermal oxidizer (RTO) of a storage and transportation exhaust gas treatment project contracted by Yurcent Environment in a refining and chemical company in Shandong Province is used to treat the exhaust gas from storage tanks, loading and sewage in the factory area. Since 2021, the project has been operating continuously and stably with ultra-low emissions, with a purification efficiency of over 99% and thermal efficiency up to 98.2%, achieving standard emission of non-methane total hydrocarbon <20mg/m³. The regenerative thermal oxidizer uses rotary valve, achieving continuous and stable standard emission.

Project background

The refining and chemical company is located in Dongying City, Shandong Province, with a processing capacity of 7.1 million tons/year. Its main products include national VI diesel, liquefied gas, hydrogenated naphtha, sulfur, sulfuric acid, petroleum coke, needle coke, etc.

The company conscientiously practices the concept of “ green waters and green mountains are golden mountains and silver mountains”, actively builds clean, efficient, low-carbon and circular green enterprise, and builds resource saving, environmental friendly ecological civilization enterprise.

Source of exhaust gas

Plant wide storage, loading area, sewage treating system, stripping sour water storage tanks.

Design scheme

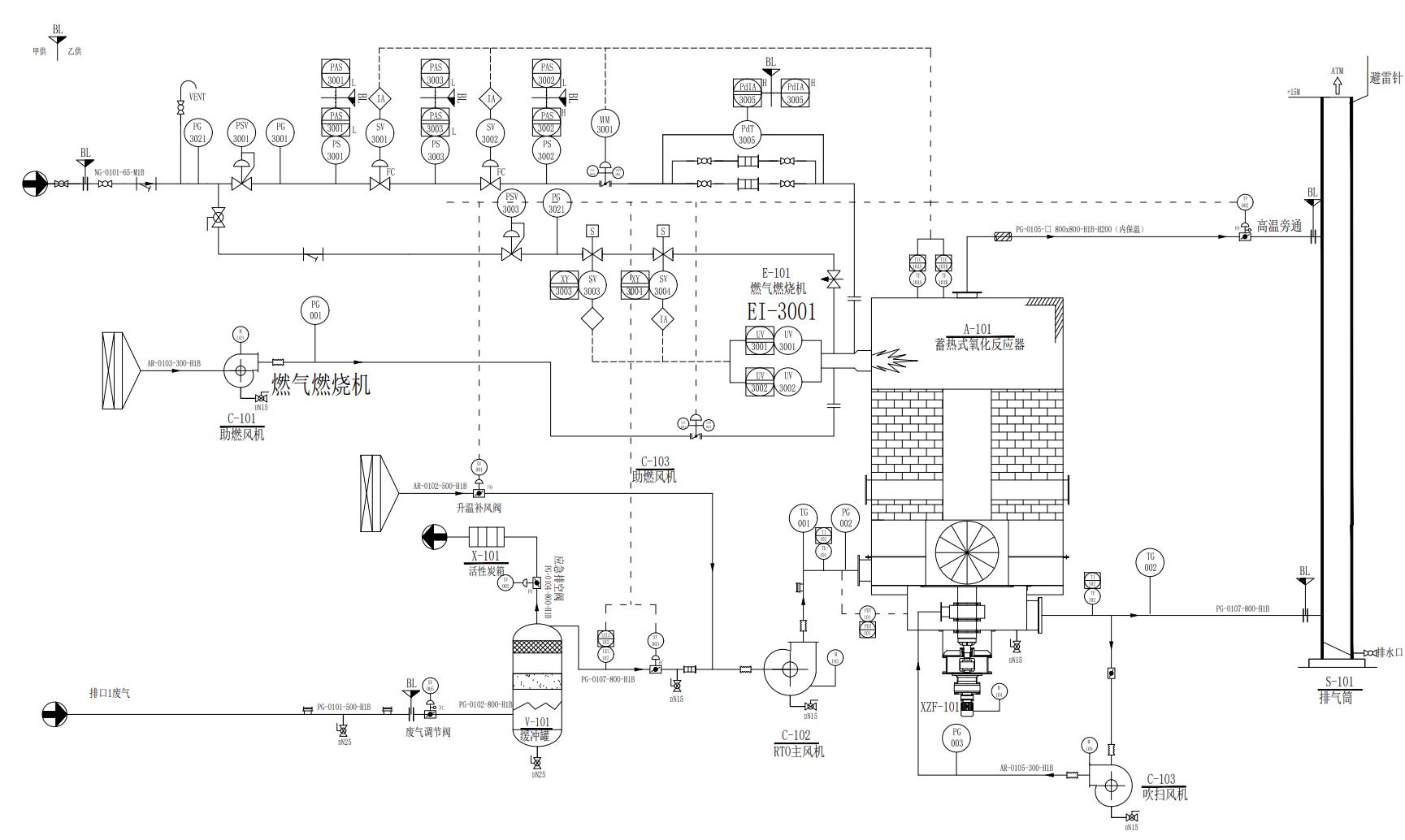

The processing capacity of the project is m³/h,adopts the treatment process of ”low temperature diesel absorption+ alkali liquor absorption desulfurization+ total hydrocarbon concentration homogenization+ Regenerative thermal oxidization(RTO)” to deeply treat and incinerate the exhaust gas from plant wide storage tanks, loading area, sewage treating system and stripping sour water storage tanks. All the light oil storage tanks are equipped with nitrogen seals to control the oxygen content of the exhaust gas. After absorbing and recovering some hydrocarbons by 1600Nm³/h diesel, the exhaust gas enters RTO for incineration treatment. After technical screening, the third generation technology product--Rotary Valve RTO was selected for the project.

Figure1 RTO skid mounted equipment

The advantages of Rotary Valve RTO

The third generation technology product—Rotary Valve RTO has excellent performance in various aspects such as operational safety, environmental compliance and stability, operational stability, and economy. The technical comparison of the products are as follows:

RTO type | Two-bed RTO | Three-bed RTO | Rotary Valve RTO |

Technology iteration | First generation | Second generation | Third generation |

Numbers of regenerative chamber | 2 | 3 | 12 |

Piping pressure fluctuation | ±500Pa | ±250Pa | ±25Pa |

Occupation of land( based on two-bed RTO) | 100% | 130% | 65% |

Weight( based on two-bed RTO) | 100% | 150% | 80% |

Comprehensive thermal efficiency | 84% | 92% | 95% |

Maximum purification efficiency | 95% | 99% | 99.5% |

Structure | 4 valves | 9 valves | 1 valve |

Maximum treating range | <1g | <5g | <10g |

Thermal efficiency | 90% | 95% | 97% |

Valve switching times per year | 350,000 times | 520,000 times | / |

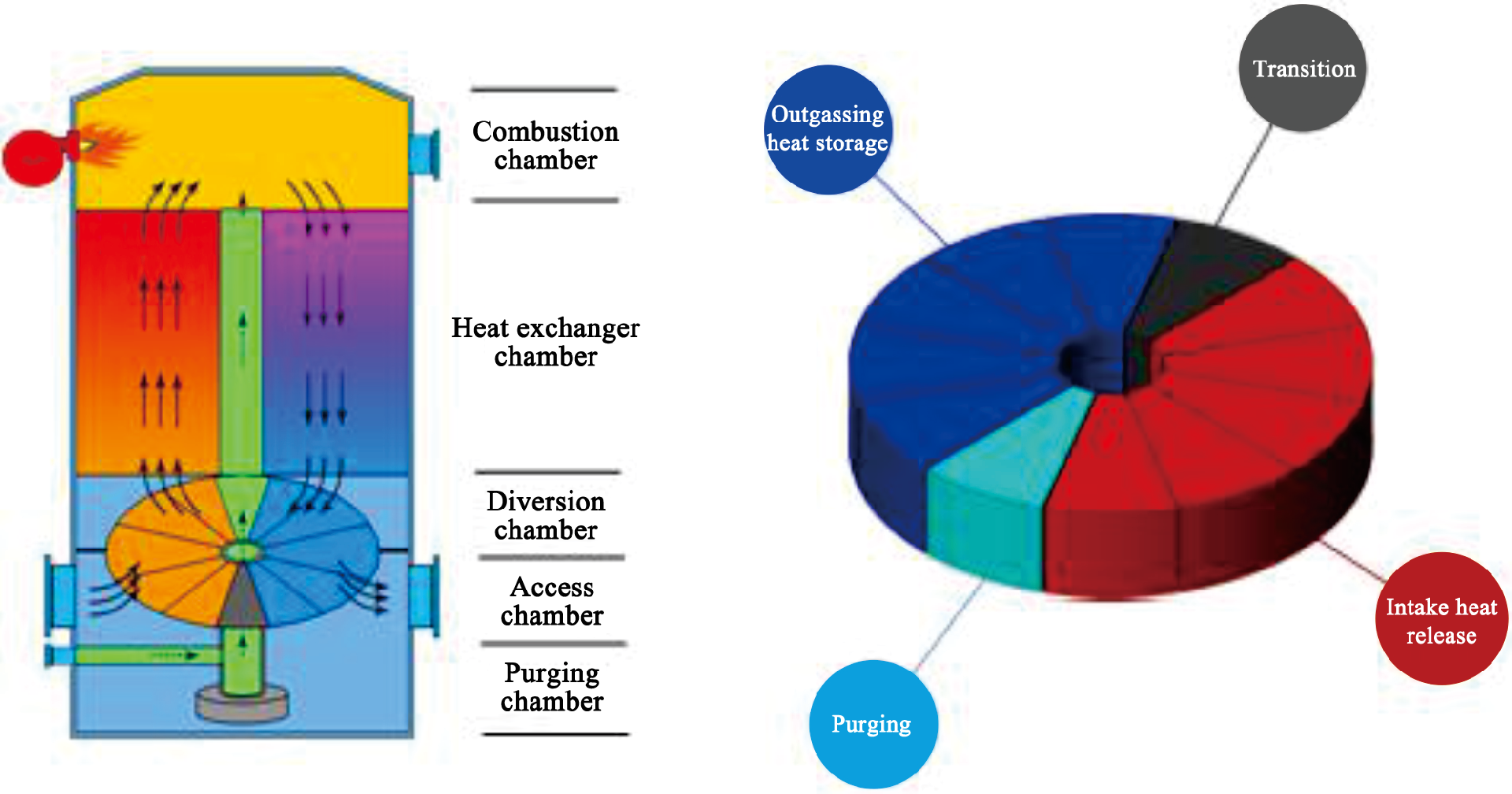

Figure2 Rotary Valve RTO structure diagram

Rotary Valve RTO was mainly composed of combustion chamber, ceramic packed bed, rotary valve, combustion system, etc. As shown in figure 2, the furnace body was divided into 12 chambers, of which 5 chambers for exhaust gas incoming, 5 chambers for purified gas outgoing, 1 for cleaning,and 1 for isolation. Rotary gas distribution valve is driven by motor to rotate continuously and uniformly. Under the action of distribution valve, the exhaust gas was switched between 12 chambers continuously and slowly. The sealing structure of Rotary Valve RTO adopts lip rubber seal, and the sealing material is made of wear-resistance, temperature-resistance and corrosion resistance materials.

Figure3 Process flow chart

Operation

The project has been running since June, 2021. Based on the analysis of the 23 months operation, the practice has proved the progressiveness of the third generation technology product— Rotary Valve RTO :

1 、The purification efficiency is higher than 99%, and the measured value of the chimney outlet is stable below 20mg/m³.

2 、The thermal efficiency is higher than 98.2%.

3 、Small land occupation

4 、Small temperature difference between the RTO inlet and outlet.

5、 Reliable and stable operation of the RTO device.