On August 11, 2022, a VOCs treatment project for a new energy material plant contracted by Xi’an Yurcent Environmental Technology Co., Ltd. successfully pass the FAT, reached various indicators agreed in the contract, and was successfully put into operation.

Project background:

This project has a total investment of 360 million yuan, and covers an area of about 99.8 mu (66564 square meters). It belongs to “Special Plan for High Quality of Manufacturing Industry in Fujian Province During the 14th Five Years Plan”. The project construction is highly consistent with carbon neutral and carbon peak polices. The project complement the upstream and downstream industrial chain of new energy batteries in Fujian Province, which will promote the construction of innovative demonstration zones for new energy material industry in Fujian Province and drive the rapid development of new energy battery industry in Fujian Province. The project planed to expand a set of RTO with a processing capacity of 50000Nm3/h to treat the exhaust gas generated by the project and its supporting projects.

Source of exhaust gas:

The exhaust gas comes from various production lines, mainly including diethylene glycol, propylene oxide, epoxy resin, ethylene oxide, methanol, polycarbonate, dimethyl carbonate, diethyl carbonate, vinyl carbonate, ethanol, ethylene glycol, etc.

Design scheme:

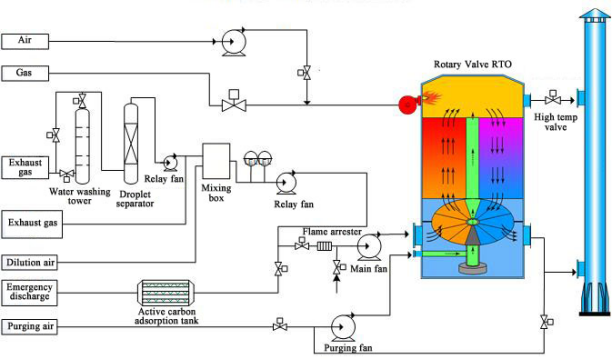

The air volume of the project is 15332.1Nm³/h, and the maximum concentration of the mixed exhaust gas is 24129.93mg/m³, with a average concentration not exceeding 15000mg/m³. The project adopts the technical route of “water washing inerting air distribution + efficient demisting buffer + Rotary Valve RTO” to treat the VOCs exhaust gas. XI'an Yurcent Environmental technology Co., Ltd. conducted system design based on self-developed and proprietary technology “Small Volume Safety Air Distribution Technology”, and determined the oxygen supplement and dilution volume was 50000Nm³/h. It is finally determined to use one set of 50000Nm³/h RTO.

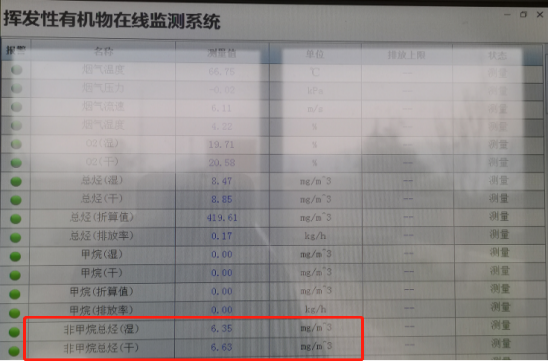

The project has been in continuous operation for 6 months. After multiple performance index tests and 24-hour continuous VOCs emission online testing every day, the emission value of non methane hydrocarbons in the purified gas after Rotary Valve RTO treatment always remained stable between 1-10mg/m3. The RTO purification efficiency has reached over 99.5%, achieving the environmental protection treatment goal with high standards.

The project’s “Small Volume Safety Air Distribution Technology” is a proprietary technology developed by our company. Our company has numerous cases of VOCs exhaust gas treatment in the production of new energy materials, with a leading number of cases and rich experience in China, and established a high-quality model project for VOCs treatment in the production of new energy materials.