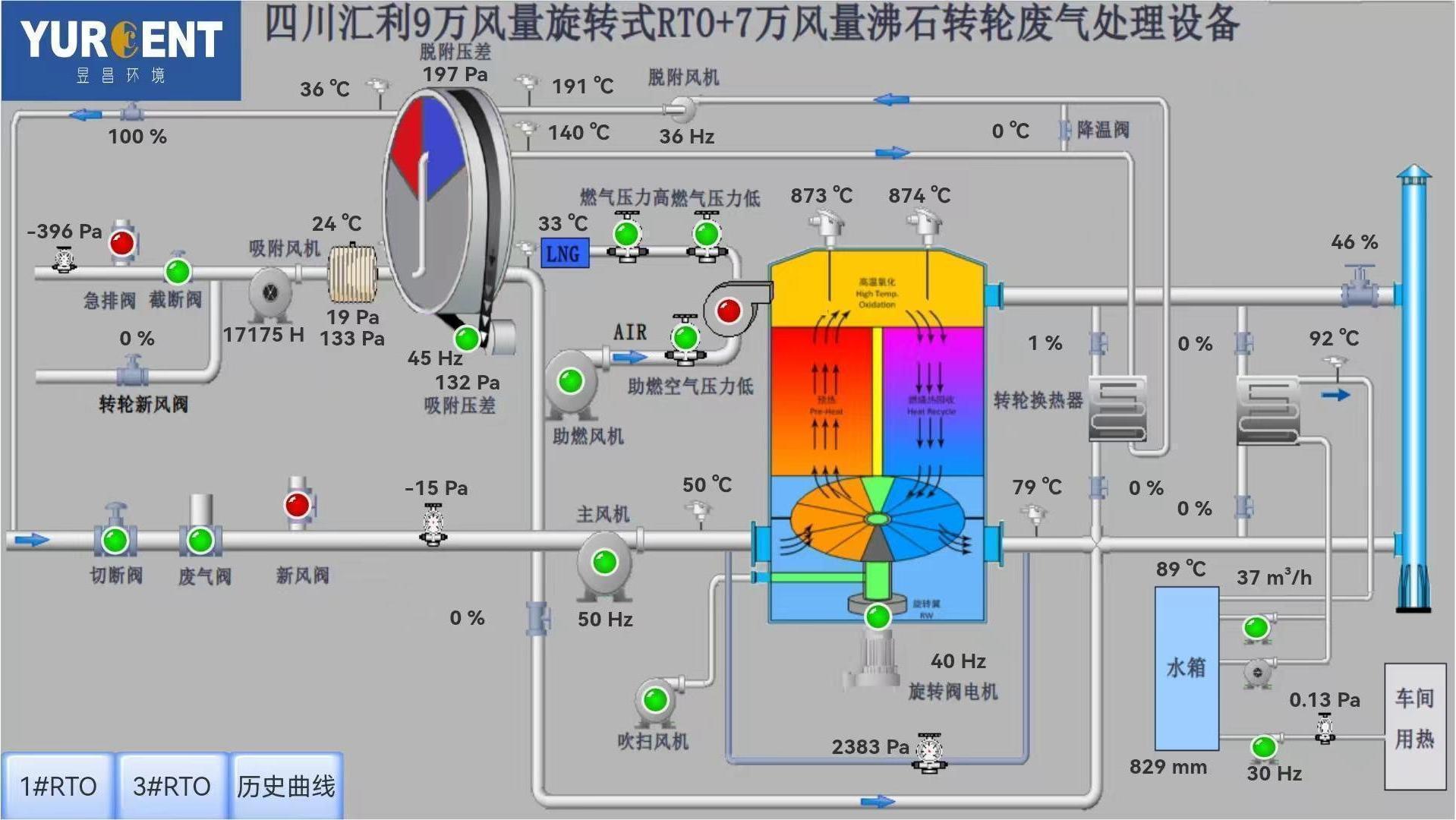

The VOCs treatment project for entire plant of Sichaun Huili Industry Co., Ltd., contracted by Yurcent Environment, adopts the technical route of “Zeolite Rotor+ Rotary Valve RTO+ Hot water waste heat recovery system” to comprehensively treat the organized and unorganized exhaust gas of the entire plant. During the long-term operation, the environmental protection treatment equipment stably discharges up to standard, and the hot water recycling device can generate hot water to supply heat for the production equipment of the entire plant. The project achieves the environmental protection treatment standards while taking into account the benefits of the waste heat recovery and utilization.

Background

Sichaun Huili industry Co., Ltd., a subsidiary of the Huili Group, is located in the beautiful and fertile “land of abundance”, Chengdu national high and new technology zone, and is a famous large-scale brand enterprise in Sichuan Province.

The company has first class production equipment, a rich product structure, strong technological research and innovation abilities and production capacity, as well as complete market network and after-sales service system. It is currently a leading brand of “one stop service” for pharmaceutical packaging in China. Huili industry is unique in the field of pharmaceutical packaging, and has important influence nationwide and globally.

Source of exhaust gas

The exhaust gas mainly comes from production equipment like printing and laminating equipment that require the use of ink and solvents, and the main pollutants VOCs are ethyl acetate, n-propyl ester, and butyl ester. The exhaust gas parameters are shown in the table bellow:

Key indicators | VOCs name | Concentration of unorgazied exhaust gas | Concentration of organized exhaust gas |

VOCs(contains solvents in ink) | Ethyl acetate | 550mg/m³ | 1930mg/m³ |

N-propyl ester | |||

Butyl ester | |||

Temperature of exhaust gas | ≤40℃ | ≤60℃ |

Exhaust gas treatment process

The project is a second purchase by Sichuan Huili Industry Co., Ltd. Considering the comprehensive treatment of the entire plant and considering the energy saving , flexibility and convenience in starting up, this project is designed with three RTOs in parallel, adopting the overall treatment route of “70000m³/h Zeolite Concentration Rotor+ 40000m³/h Rotary Valve RTO+ 80000m³/h Rotary Valve RTO+ 90000m³/h Rotary Valve RTO+ Hot water waste heat recovery system” with multiple RTOs in parallel. While fully collecting the VOCs from the entire plant and comprehensively addressing the environmental issues, it facilitates flexible startup, energy conservation and emission reduction.

Treatment effect

NMHC emission concentration | Type of waste heat recovery | Waste heat recovery amount during full load operation | Waste heat benefit (equivalent to natural gas) |

≤30mg/m³ | Hot water | 1,200,000kcal/h | 495yuan/h |

Project overview

u The project adopts a comprehensive treatment of organized and unorganized exhaust gas to achieve full collection and comprehensive treatment of each pollutant discharge point.

u Efficient treatment compliance, treatment efficiency up to 99.5%, stable VOCs emission≤30mg/m³;

u The waste heat recovery adopts hot water method, which recycles and supplies excess combustion heat generated by the decomposition of VOCs to the workshop printing machine in the form of hot water to meet the heat consumption of entire printing equipment in the factory.

u Multiple RTOs are used in parallel. The gas collecting box is used to collect the organized exhaust gas discharged from the printing presses in the entire factory, and then distribute the exhaust gas to each RTO. The customer can choose to start a single RTO or multiple RTOs based on the startup situation of the printing presses in the workshop. The startup is flexible and free to switch, and the exhaust gas is treated by the most economical manner, saving energy and reducing emission.