The Regenerative Thermal Oxidizer(RTO) for the whole plant VOCs treatment project of Sinopec Beihai Refining & Chemical Co., Ltd. contracted by Yurcent Environment is used to treat the high concentration exhaust gas from storage tanks, loading and sewage in the plant area. From September, 2020, the project has been operating continuously and stably for 30 months with ultra-low emission, with purification up to 99.7%, thermal efficiency up to 96.6%, and non-methane hydrocarbon<10mg/m³. The Regenerative Thermal Oxidizer(RTO) uses Rotary Valve to achieve continuous and stable ultra-low emissions.

Background

Sinopec Beihai Refining & Chemical Co., Ltd.(hereinafter referred to as “Beihai Refining and Chemical) is located in Linhai Industrial Zone, Tieshangang District, Beihai City, Guangxi Province, and is the most important refining and chemical enterprise of SINOPEC in southwest region. Currently, Beihai Refining and Chemical has a crude oil processing capacity of 6.4 million tons per year, and its main products include gasoline, diesel, aviation kerosene, naphtha, polypropylene, petroleum coke, high-grade road asphalt, sulfur, benzene, xylene, liquefied petroleum gas, etc.

Beihai Refining and Chemical earnestly practices the concept of “Green waters and green mountains are golden mountains and silver mountains”, actively creates clean, efficient, low carbon, and circular green enterprise, builds a resource saving and environmental friendly ecological civilization enterprise, and builds a beautiful Beihai City. The company has invested 700 million yuan in environmental protection, adopted advanced clean production processes and pollutant prevention and treatment in home and abroad, and its various indicators are far superior to the national standards. Its clean production has reached world-class level, and it has become a benchmark enterprise for environmental protection in SINOPEC system. It has been awarded the “ clean production” enterprise of SINOPEC and Guangxi Autonomous Region, and the “environmental protection” exemplary enterprise, and has embarked on a “win-win” scientific development path for environmental protection and economic development.

Source of exhaust gas

High concentration exhaust gas from storage tanks, loading and sewage in the entire plant area of Beihai Refining and Chemical company is collected and transported to the diesel absorption pretreatment facility for treatment. After being depressurized by pressure regulating valve, it is transported to RTO for incineration treatment. The temperature of exhaust gas is normal temperature, the amount of exhaust gas is 500-5000 Nm³/h. Total hydrocarbon(C1-C6 hydrocarbons, mainly C4), with a concentration of 2000-8000 mg/Nm³.

Designing scheme

The VOCs collection, transportation and treatment project of the entire plant of Beihai Refining and Chemical company adopts the technical route of“ collection and transportation+ diesel absorption+ alkali washing+ buffer mixing+ RTO” to treat the entire plant VOCs exhaust gas. After technical screening, the third generation technical production- Rotary Valve RTO was finally selected for the project.

Figure1 RTO skid mounted equipment

Advantage of Rotary Valve RTO

The third generation technology production, Rotary Valve RTO has outstanding performance in various aspects such as operational safety, environmental compliance and stability, operational reliability and economy. The product technology comparison is as follows:

Type of RTO | Two bed RTO | Three bed RTO | Rotary Valve RTO |

Technology iteration | First generation | Second generation | Third generation |

Numbers of regenerative chambers | 2 | 3 | 12 |

Wind pressure impact on the pipeline | ±500Pa | ±250Pa | ±25Pa |

Floor area (based on two bed RTO) | 100% | 130% | 65% |

Weight (based on two bed RTO) | 100% | 150% | 80% |

Comprehensive thermal efficiency | 84% | 92% | 95% |

Highest purification efficiency | 95% | 99% | 99.5% |

Structure | 4 valves | 9 valves | 1 rotary valve |

Maximum concentration treatment range | <1g | <5g | <10g |

Thermal efficiency | 90% | 95% | 97% |

Annual valve switching times | 350,000 times | 520,000 times | / |

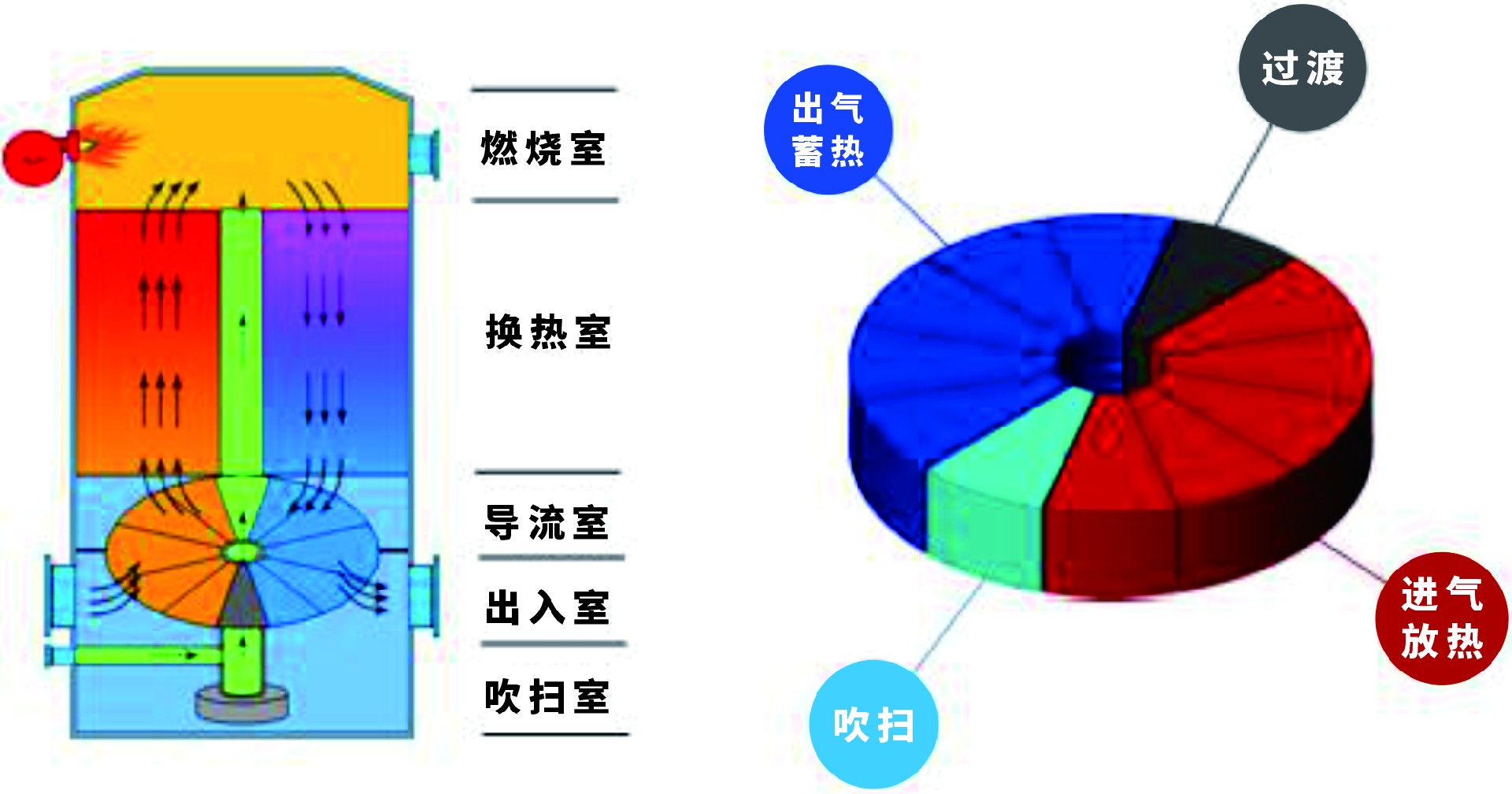

Figure2 Structural diagram of Rotary Valve RTO

Rotary Valve RTO is mainly composed of a combustion chamber, a ceramic packed bed, a rotary valve and a combustion system. As shown in figure 2, the furnace body is divided into 12 chambers, including 5 chambers for exhaust gas inlet, 5 chambers for purified gas outlet, one for cleaning and one for isolation. The rotary exhaust gas distribution valve is driven by a motor to continuously and uniformly rotate. Under the action of distribution valve, exhaust gas slowly and continuously switches between 12 chambers. The sealing structure of Rotary Valve RTO adopts lip type rubber seal, and the sealing material is made of wear-resistant, temperature-resistant and corrosion-resistant materials.

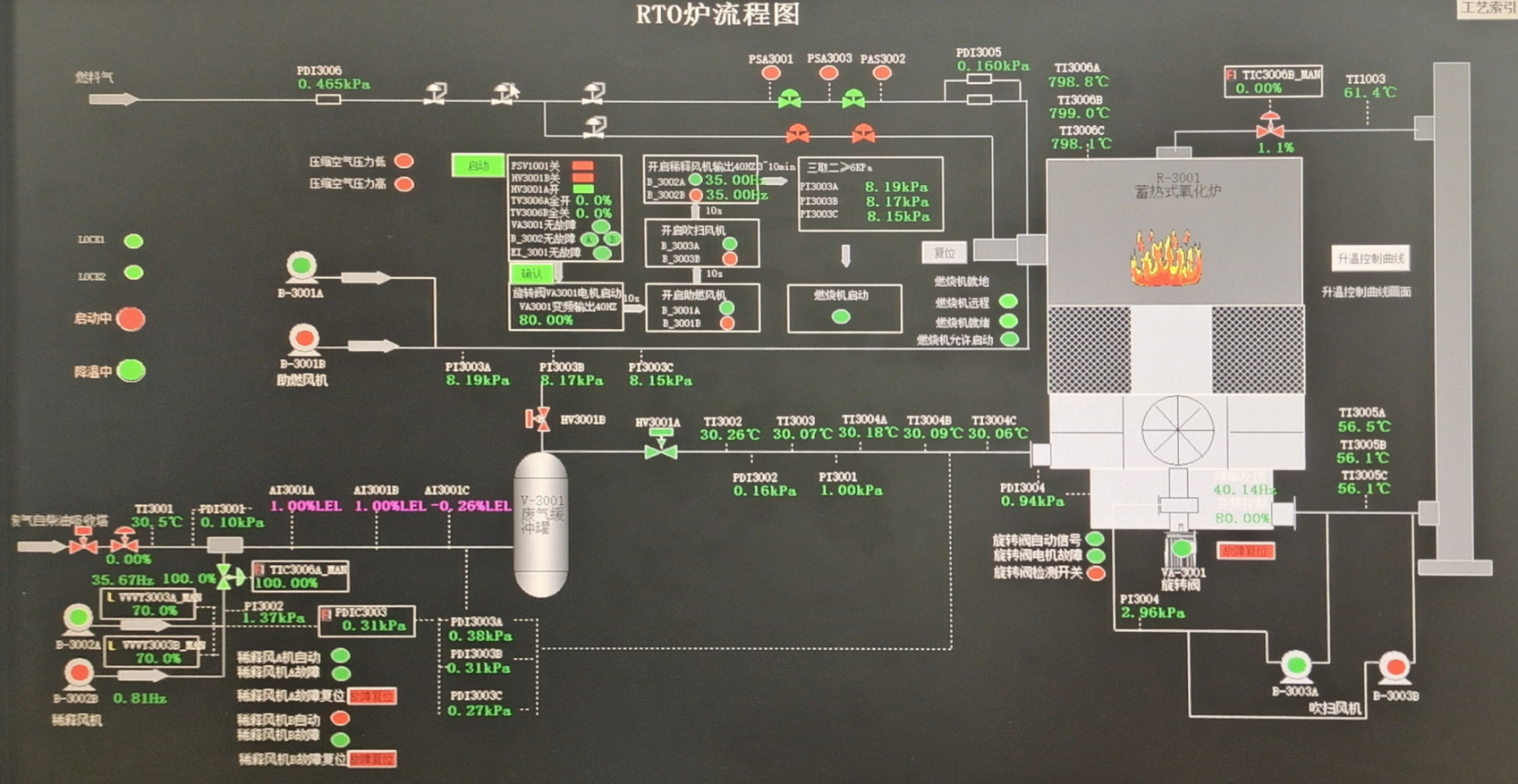

Figure3 Process chart of RTO skid mounted equipment

Operational aspect

The project has been put into operation since 2020. Based on the analysis of 30 months’ operation, the practice has proved the progressiveness of the third generation technology product-Rotary Valve RTO: 1.The purification efficiency can reach up to 99.7%, and the measured value at stack oulet is stable and lower than 10mg/m³ for a long time; 2.The thermal efficiency is up to 96.6%; 3. Small floor area; 4. Low temperature difference between RTO inlet and outlet, high energy saving of the equipment; 5. The RTO device operates stably and reliably.