The VOCs treatment project of Shandong Dacheng Bio-chemical Co., Ltd., contracted by Yurcent Environment, has been successfully operates for 3 years as of February, 2023. The non-methane hydrocarbon of tail gas is stable within 20mg/m3, and NOX is stable within 10mg/m3, effectively achieving the environmental protection goal.

Project background

Shandong Dacheng Bio-chemical Co., Ltd. is a national designated pesticide manufacturer integrating research and development, production and sales. The predecessor of the company is Shandong Dacheng Pesticide Co., Ltd., a wholly owned subsidiary of Chinese Chemical Group. It is a key backbone enterprise of pesticide and chemical industry in China. The main products are chlorothalonil, aluminum phosphide, chemical intermediates, pesticide preparations, etc.

Source of exhaust gas

The process unit exhaust, unorganized exhaust gas, waste ammonia water of 4000 t/a chlorothalonil project.

Design scheme

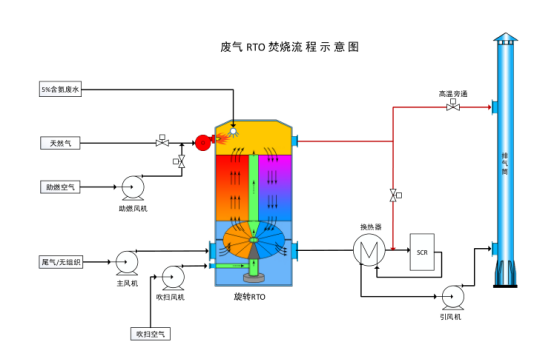

According to the characteristics of exhaust gas and the requirements of demander, Yurcent adopts the incineration process represented by Rotary Valve RTO , i.e. Rotary Valve RTO+SNCR denitration + SCR denitration = standard emission.

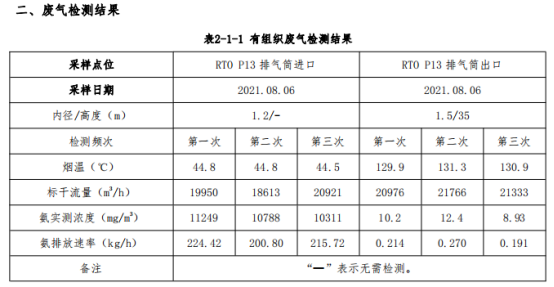

1、The exhaust gas and unorganized exhaust gas from production unit enter RTO for incineration.

2、The ammonia-containing waste water directly enters RTO oxidation chamber through atomization system for treatment, forming SNCR high temperature denitration. The denitration is completed while the nitrogen-containing waster water is treated, achieving a win-win situation of waste treatment and gas-liquid dual treatment, and reducing the treat load of RTO terminal SCR.

3、RTO exhaust is discharged through 35m chimney after deep denitration of SCR and reaching standard.

The design volume of the project is 60000m³/h. Due to the complex composition of exhaust gas and its corrosive components, the RTO battery limit is made of anti-corrosion materials as a whole.

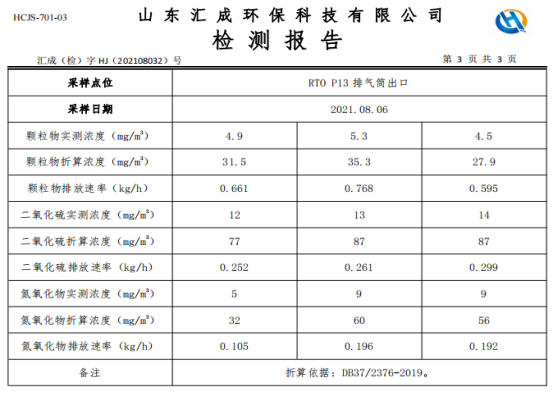

Operational aspect

By February, 2023, this project has been in stable operation for 3 years. The non-methane hydrocarbon of tail gas is stale within 20mg/m3, NOX stable within 10mg/m3. The energy consumption of equipment operation is low, and the ammonia consumption of SCR is low. The Rotary valve, the core component of Yurcent RTO, has not had any fault during its 3 years of operation. The equipment has high operating stability and the demander is very satisfied with the operation effect.