The whole factory VOCs treatment project of Shanghai Zijiang Color Printing&packing Co., Ltd. contracted by Xi’an Yurcent environmental technology Co., Ltd., has been in stable operation since December 12, 2022. The Rotary Valve RTO adopted has high purification efficiency and high thermal efficiency. The online monitoring value of non-methane hydrocarbon is stable ≤20mg/m³ with ultra-low emission. The waste heat generate steam 15t/d, which is equivalent to 3600 yuan/d, and realizing double benefits of environmental protection standard and waste heat recovery.

Shanghai Zijiang Color Printing & packing Co., Ltd. has more than 50 sets of production equipment for printing, film blowing, aluminizing, laminating, slitting and bag making, all of which are imported from Japan, Germany, Italy and other places, and are at the international advanced level. Shanghai Zijiang Color Printing & packing Co., Ltd. mainly engaged in research, development, production, and sales of flexible package materials and production, and provides flexible package solutions for food, medicine, daily chemicals, pesticides and other industries. It is an international flexible package group with strong competitiveness.

Exhaust gas source

The exhaust gas mainly comes from printing, compounding, extrusion and other production equipment that need to use ink and solvents. The main pollutants VOCs are ethyl acetate, n-propyl ester and isopropanol.

Exhaust gas treatment process

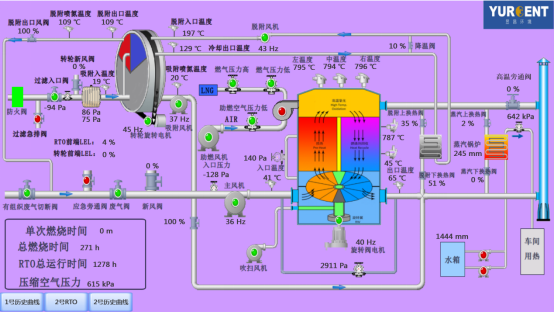

Yurcent environment has been deeply involved in VOCs treatment in printing industry for many years, and has rich experience of VOCs treatment in printing industry. This project adopts organized exhaust gas LEL air reduction and concentration method to optimize the exhaust gas of printing and compound machine ovens, reduce the exhaust gas volume, increase the exhaust gas concentration, and the exhaust gas is directly sent to Rotary Valve RTO for incineration and up-standard emission. The unorganized low concentration exhaust gas near the printing and compound machines, ink mixing room and hazardous waste room ambient air are concentrated by Zeolite Rotor. This project aims to control and collect unorganized exhaust gas of the whole plant, purify the organized exhaust gas efficiently, and convert the waste heat generated by exhaust gas to steam for the heat of workshop equipment, namely “50000m³/h Rotary Valve RTO+1.5t/h steam waste heat boiler” and “10,0000m³/h Zeolite Rotor+ 70000m³/h Rotary Valve RTO+2t/h steam waste heat boiler” system。

Treatment effect

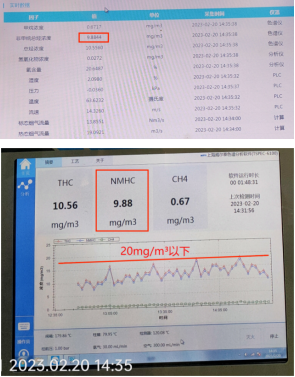

Treatment efficiency | NMHC emission concentration | Waste heat recovery type | Amount of waste heat recovery | Benefit of waste heat recovery(according to 240 yuan/t) |

99% | ≤20mg/m³ | Steam | Average 15t/day | 3600 yuan/day |

Project overview

u This project adopts organized and unorganized exhaust gas comprehensive treatment to achieve the full collection and treatment of each VOCs pollutant discharge point;

u Efficient treatment and compliance, and the online monitoring of emission value is stable ≤20mg/m³;

u The adopted steam waste heat boiler recycles the excess combustion heat in form of steam into the pipe net to supply the heat for workshop equipment and generates waste heat benefit of about 3600 yuan every day.

u In full response to the notice issued by Provincial Department of Emergency Management and Provincial Department of Ecological Environment on the issuance of the Safety Technical Requirements for Regenerative Thermal Oxidizer (RTO) System (Trial) (Su Emergency (2021) No. 46), the Chemical Engineering Design Institute is responsible for the completion acceptance to ensure the system safety.