The VOCs treatment project of Shandong Yishou Labor Protection Supplies Co., LTD. Contracted by Yurcent has been running steadily for a long time, with the purification of more than 99.5%, and the goal of environmental protection has been achieved with high standards.

1. Project background

Shandong Yishou Labor Protection Supplies Co., LTD., founded in 2009, is a modern enterprise specializing in the research, development, production and sales of latex dipped gloves. The company is located in Gaomi Economic Development Zone, Shandong Province, the hometown of labor protection supplies. The factory covers an area of 23000 square meters, has 4 automatic latex dipped gloves production lines, and initially has an annual production capacity of 35,000,000 pairs of gloves. The main products are cotton yarn nylon latex, cotton wool latex, cotton yarn nylon nitrile, cotton wool nitrile and various PVC gloves.

A large number of chemical auxiliary materials are used in the production process of latex dipped gloves, which will produce harmful VOCs such as xylene, methanol, acetic acid, not only causing waste of raw materials but also polluting the atmospheric environment.

The use of Regenerative Thermal Oxidizer(RTO) can not only ensure that the exhaust gas is treated and discharged up to the standard, but also recycle the heat energy generated by decomposition of exhaust gas, so as to achieve the dual goals of environmental protection and energy conservation.

2. Source of exhaust gas

Xylene, Methanol, acetic acid, kerosene, etc.

3. Design scheme

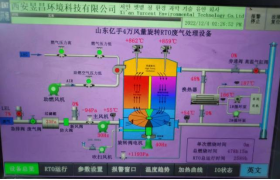

Workshop closed collection+ single 40000m³/h Rotary RTO+ tandem heat conduction oil heat exchange system.

4. Operational aspect

After commissioning, the equipment has operating stably and normally for a long time, and the environmental protection goal has been achieved with high standards. In terms of energy conservation, Yurcent Rotary RTO steadily and continuously supplies 187℃ heat transfer oil, comspletely replacing the original boiler, which can save 950,000 yuan of natural gas cost ever year.

5. Treatment effect

After RTO treatment, total hydrocarbon:2.84mg/m³; non methane hydrocarbon:2.53mg/m³;

The emission data is stable and up to standard

The “unorganized closed collection”, “flow rate and concentration control technology” and “RTO condensate drainage technology” are characteristic technology of this project. Yurcent has accumulated rich experience in the exhaust gas treatment of labor protection latex dipped gloves industry, which can give consideration of both environmental protection and energy conservation. This project has set up a environmental protection model project for the labor protection latex dipped gloves industry.